">

">

You can find information about the research and development activity of our Institute and Faculty by clicking on the sliding menus.

Research and development in the Faculty of Materials Science and EngineeringCurrently running projects:

- FORR-ÁSZ: An R&D project aiming to develop environmentally friendly soldering materials from primary and secondary resources to the automotive industry (TÁMOP-4.2.2.A-11/1/KONV-2012-0019) http://www.forr-asz.uni-miskolc.hu/

Finished projects:

TÁMOP projects

- Improving the quality of higher education based on the development of Excellence Centers in strategic research fields of the University of Miskolc.

TÁMOP-4.2.1.B-10/2/KONV-2010-0001) http://kivalosagi-kozpontok.uni-miskolc.hu/

- Building and maintaning the Technology- and Knowlgedge Transfer Center at the University of Miskolc

(TÁMOP-4.2.1-08/1-2008-0006) http://web.alt.uni-miskolc.hu/tudasprofit/

- Designing and on-line publishing complex, digital modules of competence based curriculum in the fields of materials-, nano-, and mechanical technologies.

(TÁMOP-4.1.2-08/1/A-2009-0001) http://web.alt.uni-miskolc.hu/tananyag/

- Improving the quality of higher education based on the development of Excellence Centers in strategic research fields of the University of Miskolc. (TÁMOP-4.2.1.B-10/2/KONV-2010-0001) http://kivalosagi-kozpontok.uni-miskolc.hu/

- Aligned quality improvement of scientific workshops at the University of Miskolc.

(TÁMOP-4.2.2/B-10/1-2010-0008) http://www.tehetseggondozas.uni-miskolc.hu/

TIOP projects

- Complex renewing of the national and international competitiveness of the University of Miskolc. (TIOP 1.3.1-07/1-2F-2008-0005) http://www.uni-miskolc.hu/uni/dept/TIOP.4/

- Infrastructural and informatical improvement of the Excellence Centers at the University of Miskolc.

(TIOP -1.3.1-10/1-2010-0012) http://www.uni-miskolc.hu/uni/dept/TIOP-1.3.1-10/

Currently running projects, researches in the Institute of Metallurgical and Foundry Engineering.

FORR-ÁSZ R&D project (TÁMOP-4.2.2.A-11/1/KONV-2012-0019) aiming to develop environmentally friendly soldering materials from primary and secondary resources to the automotive industry has started at March, 2013.

Prof. Dr. Tamás Kékesi, Head of the 4th Scientific Workshop.

Two of the Scientific Workshops operates in the Institute of Metallurgical and Foundry Engineering. One works on producing high purity tin to the lead-free soldering technologies with the direction of Dr. Tamás Kékesi. Dr. Tamás Török and his research group deals with surface preparation for soldering. The project aims to sustainably improve the quality of soldering. The program made and stabilized workplaces in the North-East regions of Hungary.

The syndicate realizes common research programs in teamwork with economical organizations: helps to create supply for the Hungarian research society and introduces young researchers. In additions to this, the program promotes the teamwork of academical, higher educational and nonprofit research research laboratories. Results of researches according to soldering and brazing are utilized by partner firms, where environmentally friendly soldering materials and technologies are important segments of the production.

Worksop bay

We also investigate drosses arising from secondary aluminum melting and foundry operations, as the metal content of secondary resource has great influence on further utilization. The final goal is to decrease the amount of drosses produced. In terms of zero emission directive we have done research work with SALKER Ltd. to use the hazardous waste in steel industry.

Non-Ferrous Foundry

The Department of Foundry stays in connenction with numerous non-ferrous foundries.

Varius investigations were carried out to solve problems of processing and improve the quality of castings by revealing issues of manufacturing processes. With the help of computerized simulations, we can easily modify the mould and discover sources of errors.

GD-OES Profiler 2 spectrometer

A modern GD-OES Profiler operates to analyze surface layers and bulk of materials.

Ross Mould International Ltd. sends mould samples weekly to be investigated.

Metallic and non-metallic surface coatings can also be analyzed with GD-OES Profiler 2. One condition must be kept in mind: flat area is needed. Generally, we investigate layers of various of galvanized parts and Ni-coatings. We regularly perform testing of enamel layers, too. We have internationally authenticated etalon samples to inspect Fe, Al, Cu based materials. Sample preparation takes place in our vacuum induction melting furnace, at maximum 2000 °C.

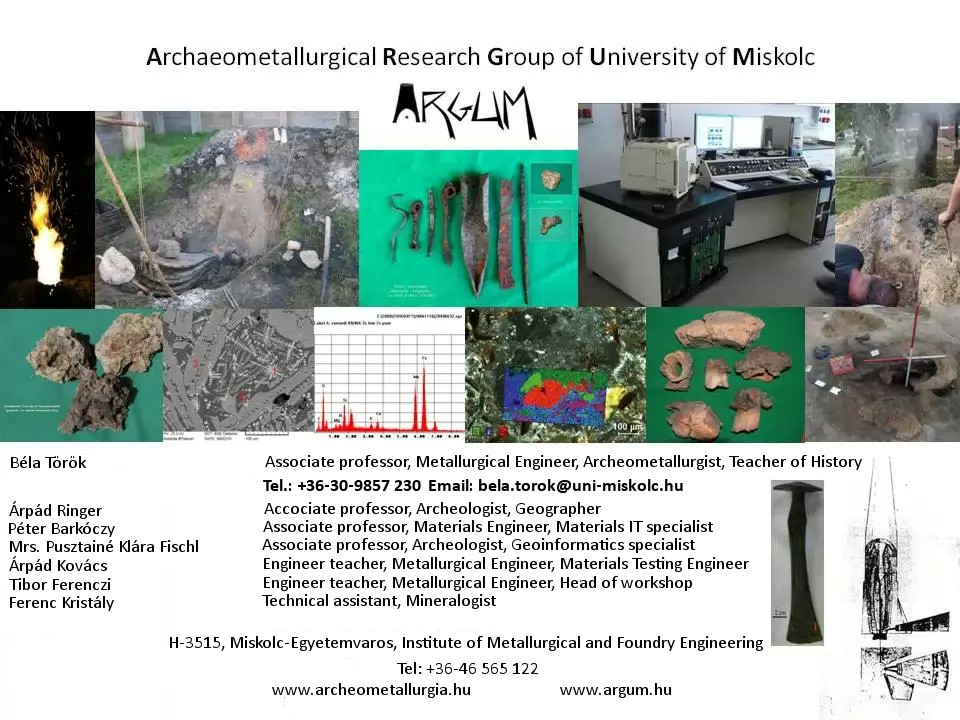

Our Institute gives place for the only archeometallurgical research group in the country, namely the ARGUM.

In the past years, many connections built between the Faculty of Arts and the Faculty of Materials Sciences and Engineering due to the interdisciplinarity of the research fields.

The latter four points sums up the activity of ARGUM:

1. Materials testing of the archeological findings: characterization, chemical, mineralogical, macro- and micro structure studying. Analysis of occurence.

2. More comprehensive description of contemporary “professional activities” including theory, phisical chemistry, metallurgy and technology.

3. Experimentation, which try to reconstruct the metallurgical and shaping technologies, to prove or deny formerly made statements.

4. Synchronisation of results with the timeline of different ethnical groups/nations.